Grinding work is inseparable from grinding medium. The grinding medium of ball mill is steel ball. We say that the steel ball of ball mill is not only the implementer of grinding operation, but also the transmitter of energy. It has great influence on the production capacity of ball mill, the quality of grinding products, and the steel consumption and energy consumption in the grinding process. Here for you to count the ball mill ball in the role of grinding.

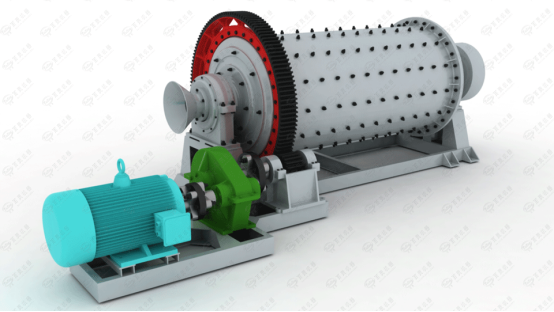

Ball mill

Ball of ball mill plays an important role in energy medium in grinding process, which determines the occurrence of crushing behavior

Grinding is a process of reducing particle size and increasing specific surface area. According to the thermodynamic principle, the increase of surface area is the process of internal energy increase, whether it can occur spontaneously, and can be realized only by external work on the ore. That is, grinding process is a function conversion process, that is, mill works on ore, which makes the energy increase in ore and deformation reaches the limit, crushing occurs. When the ore is broken, a part of the energy accepted by the ore is converted into the new surface energy of the ore particles, and most of the energy is lost in the medium space in the form of heat and sound. The grinding machine is to work for the ore and make the ore obtain energy through the energy medium a crushing medium, so the crushing medium, namely steel ball, plays an energy transfer role. If the energy transmitted by steel ball is insufficient, the ore can only be deformed. After the breaking force is withdrawn, the ore will be restored to its original state, and the crushing behavior cannot occur. Therefore, the ball determines the occurrence of the breaking behavior.

Ball Mill Balls of different sizes

As the implementer of crushing behavior, the ball of ball mill determines the quality of grinding products

Ore is an aggregate composed of a variety of minerals. The mineral crystal and the binding force between crystals determine the inhomogeneity of ore properties. According to the determination of the U.S. National Bureau of mining, the binding force on the crystal plane is only 75% of that in the crystal, and the binding force on the crystal interface of different minerals is weaker than that on the crystal plane of the same mineral. Because of the non-uniformity of ore properties, it also determines the different ways of ore fragmentation under external force.

From the point of view of modern crushing mechanics, the crushing of ore occurs when its energy density reaches the limit, and the crushing mode of ore is also related to the crushing energy, that is, the greater the crushing force of steel ball on ore is not the better. Under the action of crushing force, the crushing should be dissociated along the crystal interface between minerals, so as to achieve the main purpose of grinding. If the size of the steel ball is too large, the crushing force will be large, and the ore particles will fracture along the direction of higher energy, rather than along the crystal interface between minerals, so the crushing behavior is not selective.

At the same time, too much crushing force is easy to cause excessive crushing of minerals, resulting in the reduction of mineral processing recovery. This crushing method is obviously not required by grinding in mineral processing; If the size of the steel ball is too small and the crushing force is insufficient, the crushing behavior can not occur, and the crushing energy will disappear in the elastic recovery of the ore. only when the ore reaches the fatigue limit under the repeated action of the impact force, the crushing behavior can occur, which will inevitably lead to poor grinding effect and large energy consumption; Only in the case of moderate crushing force, the crushing behavior occurs along the mineral crystal interface with weak binding force to realize the effective separation between minerals. This kind of grinding product is needed for mineral processing, and the moderate crushing force is determined by the accuracy of steel ball size. In a word, steel ball affects the quality of grinding products.

Ball mill discharge ball

The steel ball of ball mill also affects the grinding capacity, steel consumption and energy consumption

For the fixed ball loading, the larger the ball diameter is, the less the number of balls, the less the number of hits to the particles in each grinding cycle, the less the total grinding area of ball load, the less the chances of the particles being hit and peeled, the higher the production rate of non fine grinding grade and the lower the production capacity of the mill. At the same time, the larger the ball diameter is, the greater the crushing force and the more the over grinding grade are, The grinding effect deteriorates; If the ball diameter is too small, although the number of times of hitting the ore particles in each cycle increases, due to the small energy of the steel ball and insufficient hitting force, the ore particles can not be effectively broken, and the grinding grade will also increase. The large increase of grinding area caused by small ball diameter will inevitably lead to the increase of over grinding level and the deterioration of grinding effect.

The test results in concentrator show that when the ball diameter of mill is close to the ball diameter required for grinding, it has little effect on grinding, but once the grinding medium size deviates from a certain range, the grinding effect will deteriorate sharply. Therefore, if the ball diameter is too large or too small, it will lead to the increase of too coarse and too fine grade in the grinding product, the product particle size is uneven, and the production capacity of the mill is low, which is unfavorable to the separation operation. Therefore, only when the ball size is right, can the ore particles be broken effectively and good grinding effect be achieved.

The ball size is too large or too small, in addition to the adverse effect of grinding technology, there are other shortcomings. If the ball size is too large and the crushing force is large, it is easy to cause the abnormal loss of the ball to rise. The production practice also proves that the energy consumption in grinding is often in direct proportion to the steel consumption. When the steel consumption is high, the energy consumption is also high, generally 0.035-0.175 kg / kW · h. The unit energy consumption of large ball diameter steel ball is higher than that of small ball diameter steel ball.

EXPOGROUP Supports The"GO GREEN"

EXPOGROUP Supports The"GO GREEN"